Examination and maintenance of a self-contained breathing apparatus

5

5

5

Examination and maintenance of a self-contained breathing apparatus

Our company carries out examination and maintenance of self-contained breathing

apparatus. The breathing app... More

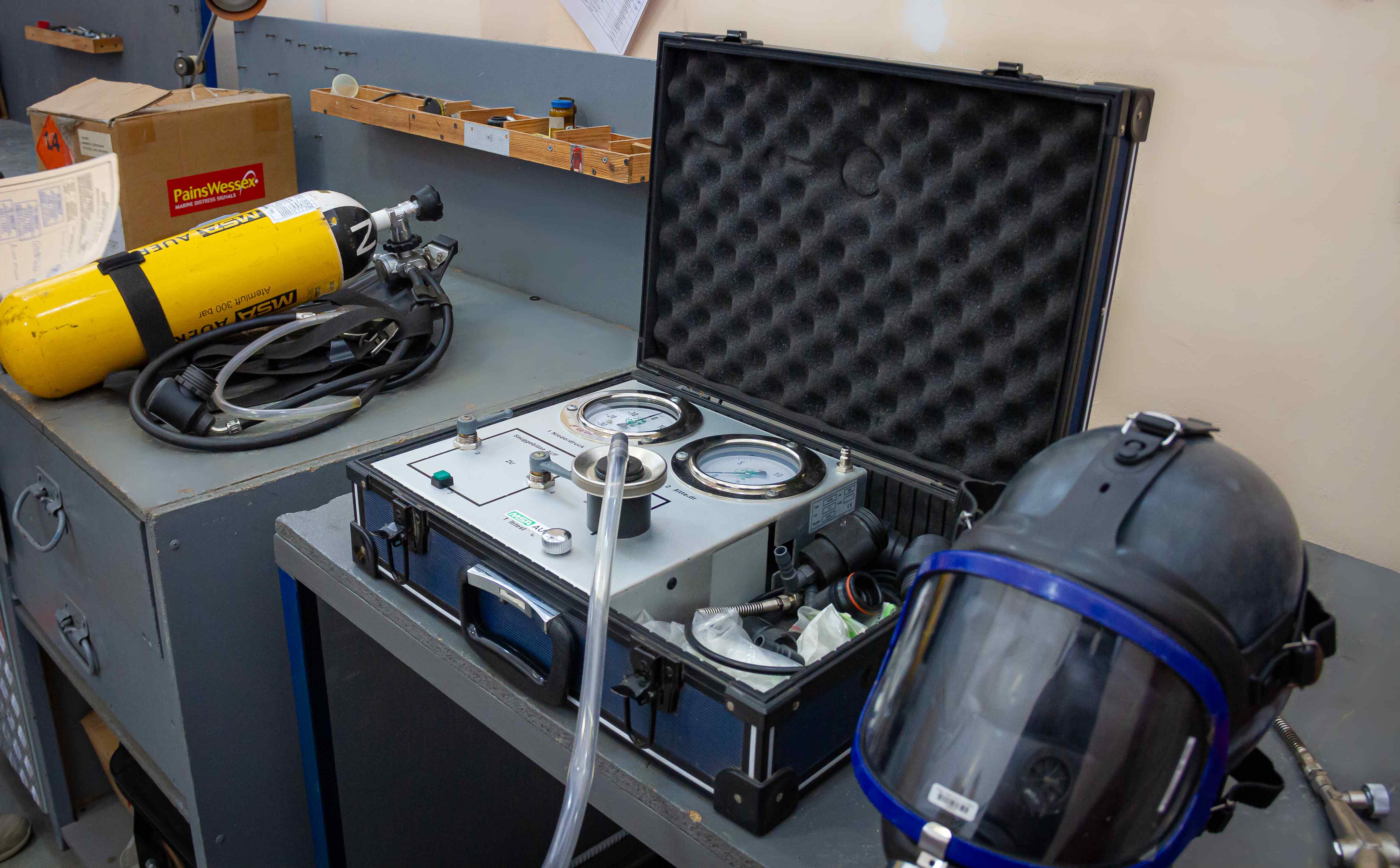

Our company carries out examination and maintenance of self-contained breathing apparatus. The breathing apparatus is dismantled by specialists for inspection and cleaning. Found faults are eliminated. We charge the assembled apparatus with compressed air and check for serviceability.

Following the check, we issue an original examination certificate for a self-contained breathing apparatus.

Following the check, we issue an original examination certificate for a self-contained breathing apparatus.

Service code:5013104100

Price:Up for discussion

Description

Air quality control must be carried out once a year. In case of negative test results, the cylinder must be recharged. After recharging the cylinder, the leakage test is applied. Every 5 years, it is necessary to carry out a hydraulic test of all steel cylinders. Composite cylinders and aluminum cylinders must be tested in accordance with the manufacturer's requirements.

We also check the elements of the basic self-contained breathing apparatus (pressure reduction safety valve, lung demand valve, full-face respirator, etc.). Clean and disinfect the necessary elements of the device.

The company's specialists will check the basic device complete with:

During the examination, the following works are performed:

Following the check, we issue an original examination certificate for a self-contained breathing apparatus.

We also check the elements of the basic self-contained breathing apparatus (pressure reduction safety valve, lung demand valve, full-face respirator, etc.). Clean and disinfect the necessary elements of the device.

The company's specialists will check the basic device complete with:

- full-face respirator;

- lung demand valve;

- pressure reducer, pressure gauge, shutter, filling valve;

- a spare cylinder;

During the examination, the following works are performed:

- Verification and testing;

- Repairs on fault detection

- Replacement of components;

- Disinfection of the device;

- Charging the cylinder, taking into account hydraulic tests;

- Calibration of the pressure gauge;

Following the check, we issue an original examination certificate for a self-contained breathing apparatus.

Related products